Pre-terminated copper trunk cable assemblies are an ideal solution for data center infrastructures and backbone applications where cable distances are reasonably predictable and can be easily determined. They play an important role in reducing installation time and cost, helping you deploy a reliable, easy-to-use copper trunking system. So, how to choose the most appropriate Ethernet cable for your network? Follow this guide, you may find the right one.

When selecting pre-terminated copper trunk cable assemblies, the first and important step is to select the types and fire ratings of materials of the assemblies. A right selection of this parameter can help minimize danger in the event of a fire. In general, you should consider whether to choose riser-rated cable or plenum-rated cable. For most data center today, riser environment is normal, where airflow is not a consideration. But for plenum spaces which do facilitate air circulations, including drop ceilings and raised floors, will generally require plenum-rated cable. Thus, consult the related departments before deciding on the type of cable for your network applications.

To choose the right termination type based on the layout of the data center or telecommunications room, and the design philosophy employed is another important step when selecting copper trunk cable assemblies. The accessibility of the active equipment including servers, switches, etc. and the proper patching solution should be considered during selection.

Jack to Jack

This termination type is typically used in cabinet-to-cabinet permanent link trunk. In general, it is installed into empty patch panels on both ends in common interconnect and cross-connect architectures. The use of patch cords is used to complete the connectivity between the active equipment and the physical layer.

Jack to Plug

Typically used for in-cabinet or cabinet-to-cabinet equipment cord harnesses, the jack-to-plug type is installed into the patch panels on one end and switch ports on the other end for switch port replication applications, eliminating one cross-connect point by having the cable plugged directly into the active equipment.

Plug to Plug

Typically used to make a direct connection between active equipment, e.g. server to switch, eliminating cross-connect capabilities. It can also be used in an open-space work area as a bundled patch cord group.

Jack to Open

Jack-to-open configuration is used in similar applications as the jack to jack. However, one end of it is “open”, which means that one end should be cut to length and field-terminated to a target termination place, such as 110-style panel, patch panel or wall plate. Field testing of the drops is necessary after the cables have been terminated in this case.

Cassette to Cassette

Typically used in cabinet-to-cabinet permanent link trunks, the cassette-to-cassette type is installed into patch panels on both ends in common interconnect and

cross-connect architectures, with cassette enabling quick installation into panels.

Cassette to Plugs

Similar configuration as the cassette-to-plug type, but with cassette on one end and modular plugs on the other end. Typically used for in-cabinet or cabinet-to-cabinet equipment cord harnesses, it is installed into patch panels on one end and switch ports on the other for switch port replication applications, enabling quick installation and removal of modular plugs into switch ports.

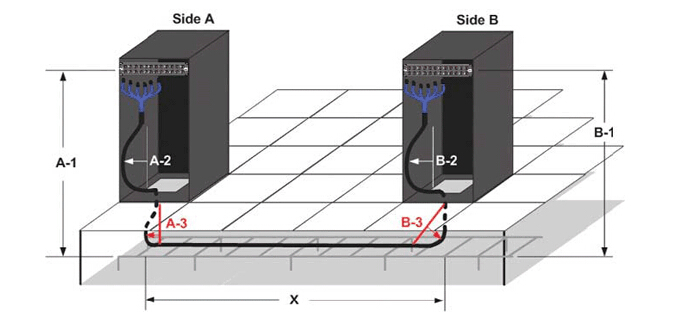

For pre-terminated copper trunk cable assemblies, the length is a very important parameter to be ordered which help users to achieve the best performance. The following picture illustrates how to calculate a trunk cable length in a Data Center environment, but similar dimensions would be considered when using a copper or fiber trunk in a backbone/riser application.

- Trunk Cable Length = (A1+A2+A3) + X + (B1+B2+B3) where:

- X —Horizontal Distance

- A1 —Vertical Distance (side A)

- A2 —Cable Slack within the cabinet (side A)

- A3 —Cable Radius transitioning out of the floor (side A)

- B1 —Vertical Distance (side B)

- B2 —Cable Slack within the cabinet (side B)

- B3 —Cable Radius transitioning out of the floor (side B)

Breakout length, namely the dimension from the end of the braided sleeve to connectors at the end of the cables. It is part of the overall length, not in addition to the length measurement. A proper breakout length should have flexibility to route the cables as needed, but not impose an additional burden in cable management. In most cases, a 36-inch breakout length is sufficient. With this dimension, the trunk remains in the vertical manager and the individual abilities can route through the vertical duct fingers and still reach across the 19-inch rack to the farthest port. While for applications outside of a rack or cabinet, a longer breakout length may be required so that the flexibility of having the connectors spread out farther apart. Usually, 48 inches or more is available.

Whether to choose staggered or even alignment types depends on your applications. When choosing staggered, to consider which side of the patch panel (left or right) the trunk will enter from. It will need to be specified if cable number one in the trunk will be the shortest or the longest cable in the stagger. In contrary, active equipment will vary with respect to the location and density of the connection ports. An even alignment for plugs ensures a uniform reach for all six cables in a trunk.

Pre-Terminated copper trunk cable assemblies are designed to improve efficiency and reduce labor cost and waste in large infrastructures with high-density cross-connection and patching systems. Of course, the prerequisite for these benefits is to select the most proper copper trunk assemblies for your copper network.

Related Articles:

Data Center Pre-terminated Copper Trunk Cable Solution

What Is Copper Trunk Cable and How to Use It?